300+

Patents Secured

2700+

Students Employed

500+

Global Partners

14

Spinoff Companies

840+

Publications

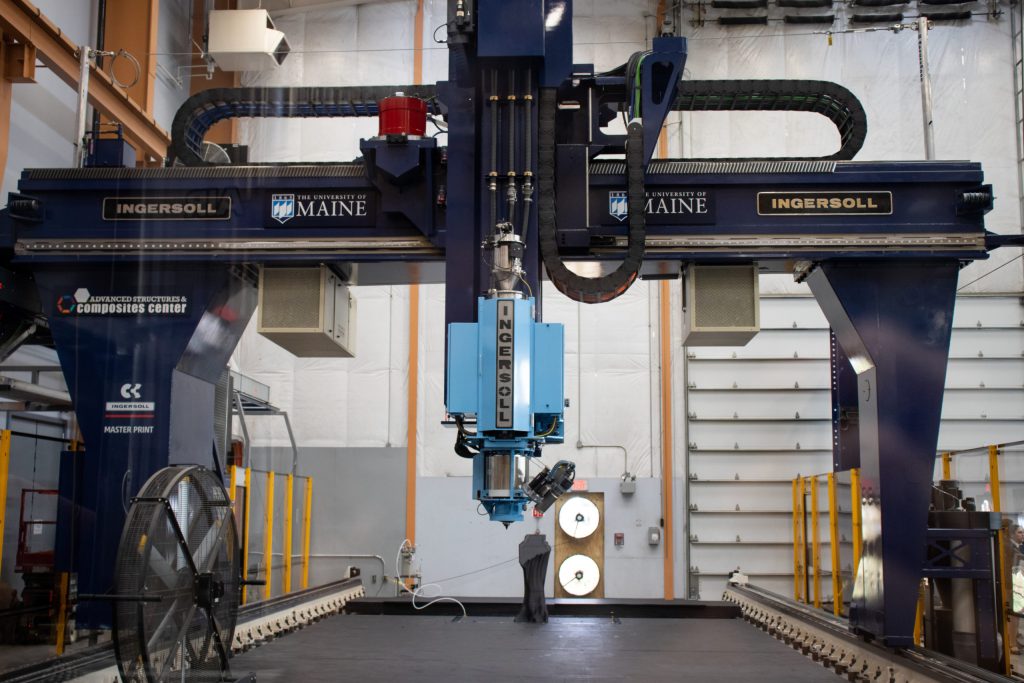

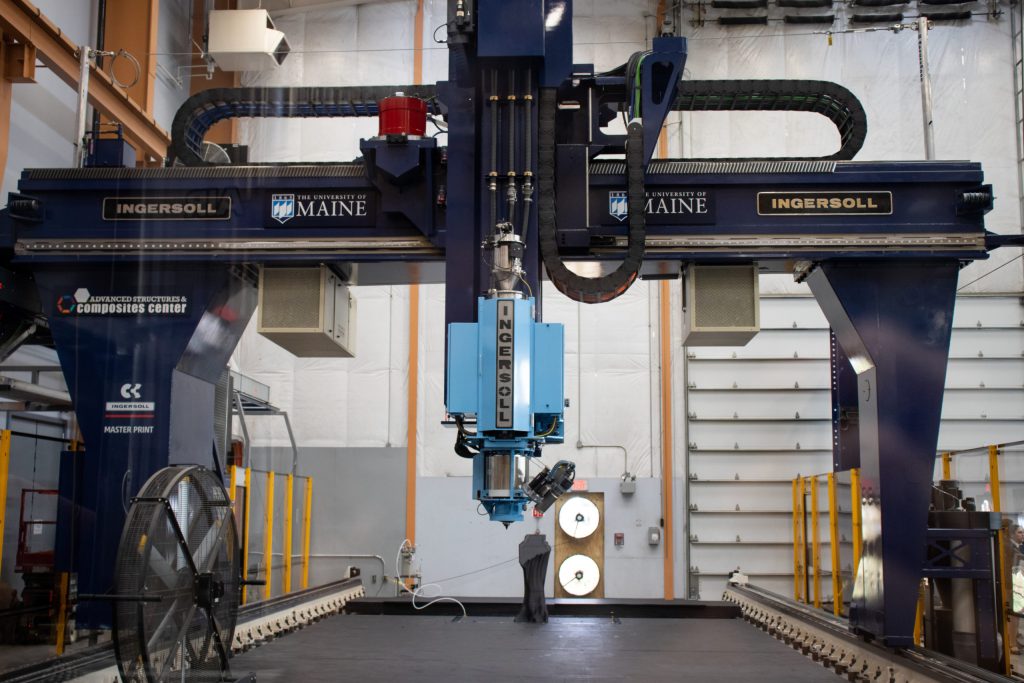

ADVANCED STRUCTURES & COMPOSITES CENTER

Home

Home

The University of Maine Advanced Structures and Composites Center (ASCC) is a world-leading, interdisciplinary center for research, education, and economic development encompassing material sciences, advanced manufacturing, and engineering of composites and structures. Since its founding in 1996 with support from the National Science Foundation, the ASCC has financially sponsored more than 2,600 students, received 120 patents, welcomed over 30,000 visitors, created 14 spinoff companies, and honored with more than 40 national and international awards for research excellence.

RESEARCH AREAS

The Matthew R. Simmons Windstorm Challenge prepares Maine’s next generation of innovators and engineers. Our annual event invites middle and high school students to design and build floating platforms for scale model wind turbines. The competition welcomes students of all backgrounds and skill levels.

PROJECT HIGHLIGHTS

TIDC

The Transportation Infrastructure Durability Center focus is on developing innovative, sustainable, next-generation solutions to improve the durability and extend the lifespan of existing and new transportation assets in New England and beyond.

SM²ART

The Hub & Spoke Sustainable Materials & Manufacturing Alliance for Renewable Technologies (SM²ART): Connecting two world-class research facilities and redefining how national laboratories and universities connect with industry.

Scaling Manufacturing

Empowering manufacturers to reach new markets with

lightweight, anti-corrosive, and infinitely shapeable

parts through continuous production of

long-fiber thermoplastic composite.

Culvert Diffuser

ASCC’s work focuses on implementing green infrastructure solutions, utilizing bio-based materials and sustainable manufacturing processes like advanced manufacturing for culvert diffusers, composite sheet piling and novel breakwater solutions.

BioHome 3D

Designed to address labor shortages and supply chain issues that are driving high costs and constricting the supply of affordable housing. Printed using abundant, renewable, locally sourced wood fiber feedstock reduces dependence on a constrained supply chain.

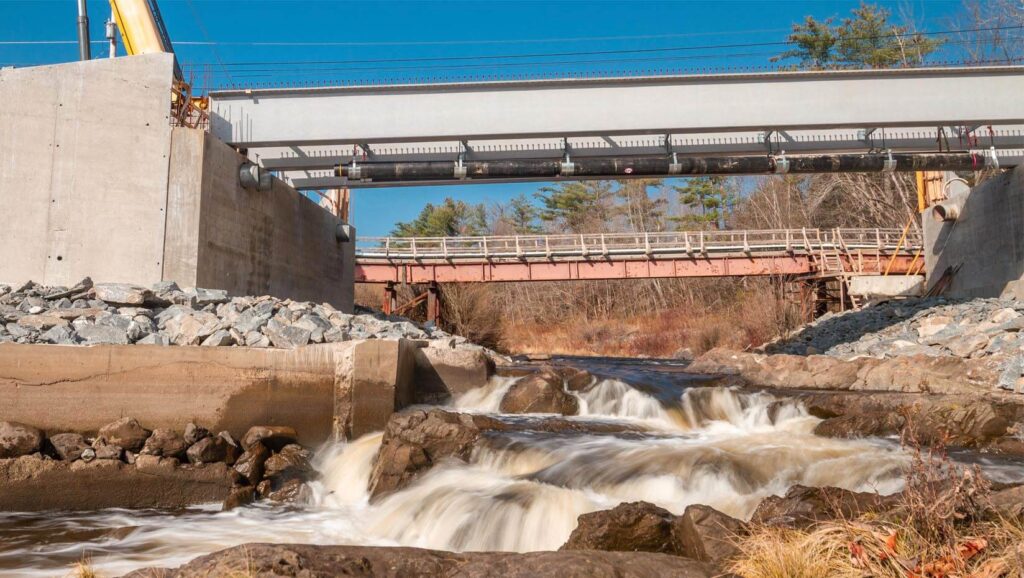

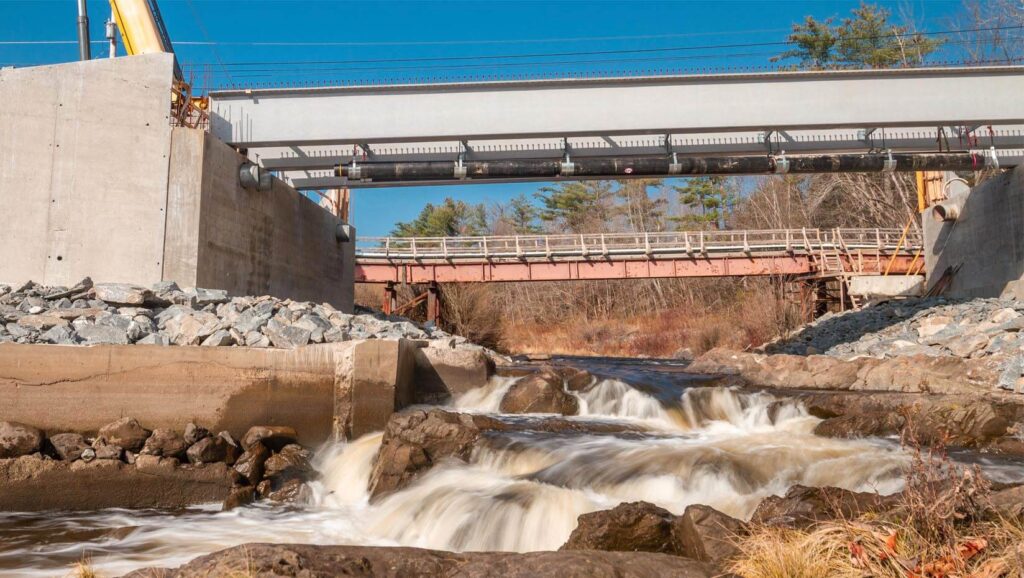

G-Beams

Fiber-reinforced polymer (FRP) tub-girders called GBeams that are corrosion resistant and designed to last over 100 years with little to no maintenance. The composite girders are lightweight, weighing as little as one-quarter the weight of steel girders.

SM²ART

The Hub & Spoke Sustainable Materials & Manufacturing Alliance for Renewable Technologies (SM²ART): Connecting two world-class research facilities and redefining how national laboratories and universities connect with industry

Scaling Manufacturing

Empowering manufacturers to reach new markets with lightweight, anti-corrosive, and infinitely shapeable parts through continuous production of long-fiber thermoplastic composite.

TIDC

The Transportation Infrastructure Durability Center focus is on developing innovative, sustainable, next-generation solutions to improve the durability and extend the lifespan of existing and new transportation assets in New England and beyond.

BioHome 3D

Designed to address labor shortages and supply chain issues that are driving high costs and constricting the supply of affordable housing. Printed using abundant, renewable, locally sourced wood fiber feedstock reduces dependence on a constrained supply chain.

G-Beams

Fiber-reinforced polymer (FRP) tub-girders called GBeams that are corrosion resistant and designed to last over 100 years with little to no maintenance. The composite girders are lightweight, weighing as little as one-quarter the weight of steel girders.

Culvert Diffusers

ASCC’s work focuses on implementing green infrastructure solutions, utilizing bio-based materials and sustainable manufacturing processes like advanced manufacturing for culvert diffusers, composite sheet piling and novel breakwater solutions.

We’re Hiring!

We are looking for people who challenge the impossible, push limits, seek meaningful work, and want to drive our Green Energy and Materials strategic plan.

JOIN US