Commitment To Maine and our Planet

We are dedicated to driving research innovation in Green Energy and Materials (GEM), to create a greener, more sustainable world while bolstering economic development in Maine and beyond. GEM is more than an initiative, it is our passion.

Patents Secured

Students Employed

Global Partners

Spinoff Companies

Publications

ADVANCED STRUCTURES & COMPOSITES CENTER

Commitment To Maine and our Planet

The University of Maine Advanced Structures and Composites Center (ASCC) is a world-leading, interdisciplinary center for research, education, and economic development encompassing material sciences, advanced manufacturing, and engineering of composites and structures. Since its founding in 1996 with support from the National Science Foundation, the ASCC has financially sponsored more than 2,600 students, received 120 patents, welcomed over 30,000 visitors, created 14 spinoff companies, and honored with more than 40 national and international awards for research excellence.

Housed in a 100,000 ft2 ISO-17025 accredited facility, the ASCC has become the largest university-based research center in Maine and among the fastest-growing research laboratories globally. The facility has expanded to include 13 integrated laboratories with more than 410 full and part-time personnel, including faculty, staff, and students. The Center pursues innovations that are meaningful to society by bringing together talented faculty, staff, and students from all corners of the UMaine campus. Enshrined in plaques in the Center’s lobby and conference rooms, the mottos “None of us is as smart as all of us” and “Students first” define our mode of operations.

The ASCC’s strategic plan, called GEM, focuses the Center’s work on Green Energy and Materials development. Through GEM, the Center is at the forefront of significant new sustainability industries in the nation. Our eight major research areas are Civil Infrastructure Durability, Advanced Wood Composites, Large-scale Bio-based Additive Manufacturing, Cellulose Nanocomposites, Advanced Structural Concepts, Structural Thermoplastics & Smart Materials, Ocean Engineering & Energy, and Structural, Material, & Wind Blade Testing. Innovations in GEM research and development position the Center to critically support the state’s ambitious efforts to be carbon neutral by 2045 and usher in a low-carbon economy.

Dr. Habib Dagher

Welcome, from our Founding Executive Director

Habib Dagher

Our strategic plan, named GEM: Green Energy & Materials, is our commitment to sustainably leverage Maine’s natural assets to solve our most pressing challenges while maximizing opportunities for students. We are committed to a sustainable future for Maine and beyond.

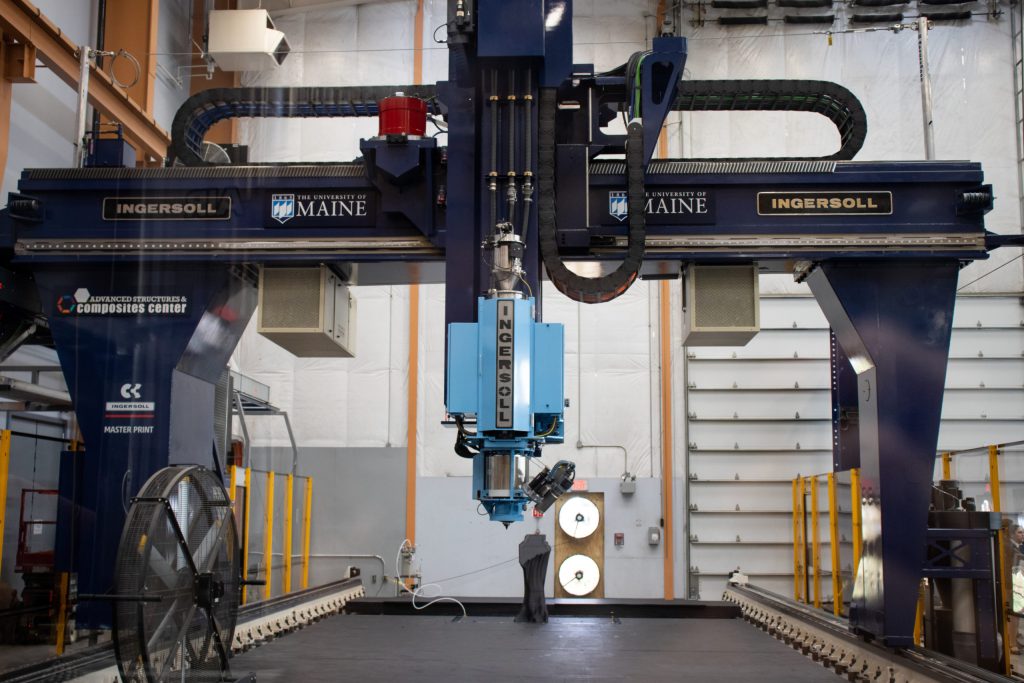

The Factory of the Future

Project Highlights

SM²ART

The Hub & Spoke Sustainable Materials & Manufacturing Alliance for Renewable Technologies (SM²ART): Connecting two world-class research facilities and redefining how national laboratories and universities connect with industry

TIDC

The Transportation Infrastructure Durability Center focus is on developing innovative, sustainable, next-generation solutions to improve the durability and extend the lifespan of existing and new transportation assets in New England and beyond.

NEAV

New England Aqua Ventus I is a floating offshore wind demonstration project to develop a clean, renewable energy source off Maine’s shores, and will contribute to the transformation of our energy sector to renewable sources, and keep our energy dollars in Maine

MMTCC

The Maine Mass Timber Commercialization Center brings together industrial partners, trade organizations, construction firms, architects, and other stakeholders in the region to revitalize and diversify Maine’s forest-based economy

NASA HIAD

HIAD (Hypersonic Inflatable Aerodynamic Decelerator) is a nose-cone-mounted inflatable structure consisting of multiple, concentric, nitrogen-filled tori that is designed to decelerate and protect spacecraft during atmospheric re-entry.

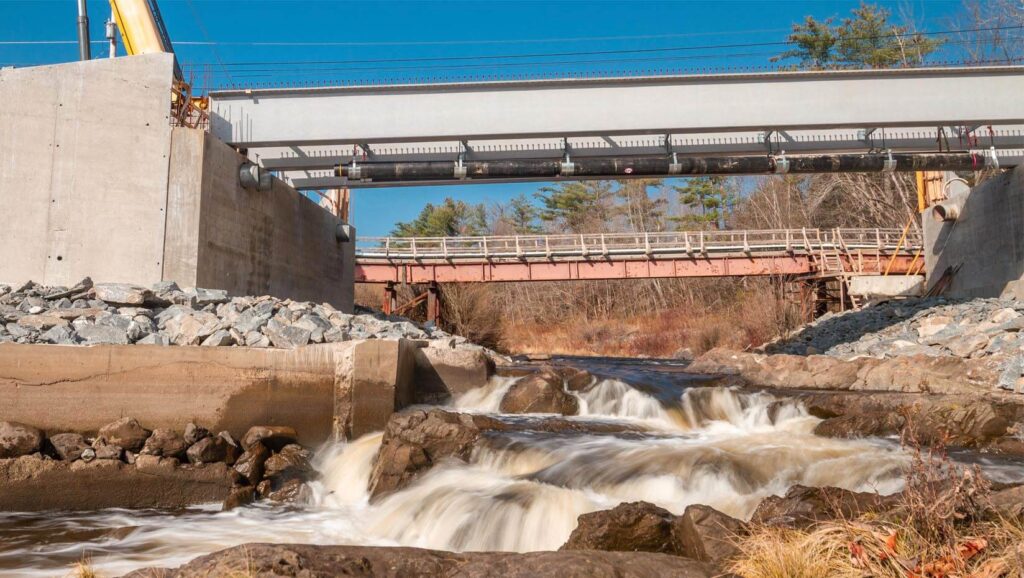

G-Beams

Fiber-reinforced polymer (FRP) tub-girders called GBeams that are corrosion resistant and designed to last over 100 years with little to no maintenance. The composite girders are lightweight, weighing as little as one-quarter the weight of steel girders.

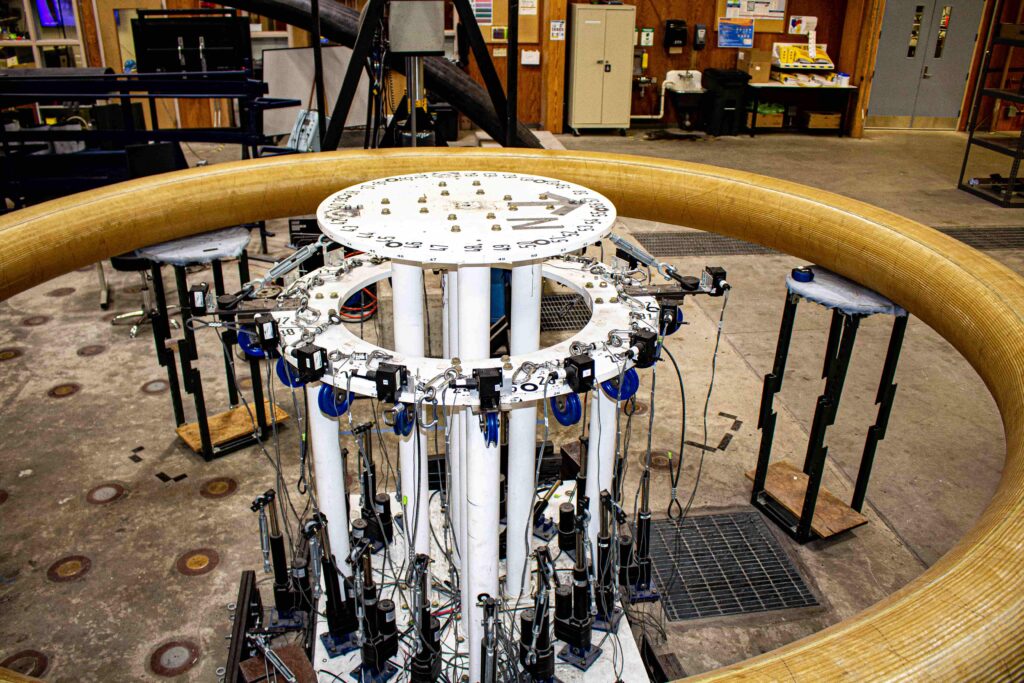

The UMaine Composites Center is an ISO 17025 accredited testing laboratory with nearly 20 years of testing experience meeting industry standards from coupon-scale to full-scale. This certifies that we have met the requirements of the IAS Accreditation Criteria for Testing Laboratories (AC89), demonstrated compliance with ISO/IEC Standard 17025:2005, and general requirements for the competence of testing and calibration laboratories, and are accredited for the test methods listed in the approved scope of accreditation.

We’re Hiring!

We are looking for people who challenge the impossible, push limits, seek meaningful work, and want to drive our Green Energy and Materials strategic plan.

JOIN US