2007 – 2008 US ITASE Field Report

Page 3

Logistics (continued)

Aircraft support: US ITASE was supported this season primarily by Basler and by Twin Otter for delivery of small items. The Basler provided support for all put-in requirements, fuel caching, and pick up of expended fuel drums. The Basler is a perfect aircraft for traverse support.

Food: Food quality was excellent this season. Luci Pandolfi prepared hot dishes for all three daily meals.

Shelters (Blue Room, Kitchen, Polar Haven): The same Berco mounted shelters available during previous US ITASE traverses were available this season. As reported in previous field reports the Kitchen and Blue Room while adequate for their purpose are far heavier than necessary and both shelters are extremely top heavy.

The Blue Room and Kitchen shelters are attached to Berco sleds by a small number of bolts that have regularly sheared or fallen out. More substantial attachments were requested following the 2006-2007 season, but no repairs were made during the put–in phase of 2007–2008.

Lehman Sleds: Qty two Lehman sleds were provided for the 2006 traverse. As in the past they were used for the heaviest loads (e.g., fuel drums) and served well.

Berco Sleds: Qty three Berco sleds were available for the 2007 traverse. As in the past the Berco sleds did well. The state of the rear hitches turned out to be a major issue in 2006–2007 and we had one failure this season. The rear hitches are designed to fail under excessive stress to save the Berco frames. One Berco rear hitch failed in 2006–2007 after having traveled >8000km. Rear hitches for each Berco were replaced, by US ITASE team members at the start of the 2007–2008 season.

Plastic sleds: Qty three Siglin designed plastic sleds were specially ordered for the 2006–07 traverse. Their intended purpose was to be for light–weight transport (e.g., empty fuel drums and air drop materials). The Siglins turned out to be excellent even for heavier loads (up to 12,000 lbs) once equipped with pallets and draw bar chains attached to the pallets. Although two pallets failed and one Siglin was slightly damaged the concept of plastic sleds proved to be very promising and four heavy–duty plastic sleds equipped with heavy–duty tow bars and rear hitching capability were requested for the 2007 season. The three 2006–07 sleds were upgraded. These sleds are relatively inexpensive compared to Bercos and Lehmans and can be shipped in pieces (although the bolt holes for assembling the sleds in the field should not be pre–drilled since the pieces have different rates of thermal expansion). For this season the Siglins were reinforced structurally. Unfortunately, lightweight carriage bolts were employed and several bolts failed necessitating stops to rip away the structural segments damaged after bolt failure. The design for the structural reinforcement seems to be successful but the quality of materials and repair were inadequate.

Mechanic’s Repairs (prepared by Josh Swanson):

- Eberspacher heater unit 12 volt. Both Fork and Dozer Cat units failed and were replaced in 2007.

- Old unit from Fork Cat needs a glow plug. It is reboxed and good for spare parts.

- Grid heater failed on the PB 11–2007 and was replaced. If a PB is used with this train again that part should be re–inventoried.

- One 25 volt coolant heater failed on the PB and was replaced.

- PB front axle has a crack on the top left gusset on the left side of vehicle. Needs a new front axle or repair by cutting a V and welding shut.

- Voltage regulator sent out for Onan generator when installed to fix an over charge on the DC side of 15.5 volts. After installed DC charger was back in range to 13.2 volts. But the AC volt range was 136–145 volts when adjusting by the dial.

- The Boom for the Ground Penetrating Radar on the front of the PB had a few failures. First one Rune tower was bent due to using the winch and the new front sled being far too heavy to be lifted. It broke apart en route and was replaced with a new extension at drill site 1. Then the front bracket broke due to the extra stress from the added leverage and weight that the new GPR sled added. This was fixed by strapping the boom directly to the plastic sheet. It appears to have been a solid fix.

- Siglin upgrade failed in route to site 2. The under plate appears to have caught a strong piece of ice shearing the carriage bolts on the right side and wrapping the metal under the sled. The upgrade was removed and the sled was used as a light haul only sled. Two rear plates were ruined later in the season with the same result. One had no weight on the rear so possible sled flex caused the weak carriage bolts to break. Recommend if this upgrade is wanted for future traverses with Siglins to use grade bolts and more of them.

- Another Siglin sled split at the welded seam in the middle. This happened last year as well on a different Siglin, same left side. Repaired by drilling end of crack and bolting in rubber strips to hold the split ends together. This sled was hauling a light load of food boxes. Last year it was a heavy load of fuel barrels.

- Magneto failed on a Herman burner. It was replaced. The spark plug insulation to the burner failed as well causing spark in wrong location or not at all and was replaced.

- Rear wiper arm replaced on Dozer Cat.

- Starter relay replaced on Dozer Cat.

- Coolant radiator and fan replaced on Dozer Cat.

- Throttle cable on fork Cat was not moving up or down. Removed and warmed up cable which freed it to move again. Water found a way in and froze it unmovable. Added alcohol in sleeve to help remove any left over moisture and to help keep from happening again.

Mechanic’s recommendations:

PB should go back to MCM to be torn apart and inspected for cracks. Have a complete full pm done including calibrations of hydraulic pressures and synchronizing of moog units. Inspection for frame cracks and cracks in axles. Bogie wheels removed and bearings inspected, replaced or repacked.

The Challenger 55s need a thorough go through. Leak down test of engine, undercarriage measurements. Track replacement and full fluids change. Batteries are old and working fine but replacement would add reliability if used on traverse again.

Fork Cat has an exhaust leak on the manifold. It has been leaking since I started with ITASE last year. Parts are here and ready to be installed. Didn't install in field due to fear of studs breaking and not being able to get them out with tools here. Decided it best to be done in a warm shop with easy outs and other tools to remove broken studs from head.

Dozer Cat needs a hydraulic cable installed from lever to valve body. It is on hand. Wasn't a priority in field since I changed hoses to a different lever control valve. Due to time restraints it may or may not be done in the field.

Communications: Primary communications this season were made using Iridium phones. HF base stations were used between vehicles and VHF for close heavy equipment use.

Deep Radar: (prepared by B. Welch, St. Olaf College): The radar system was essentially the same as previous years. Some requests for improvements to the radar sled and shelter were made this year:

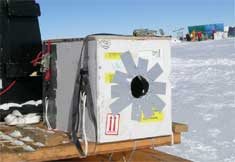

Figure 3: ICDS ice core box converted for

Figure 3: ICDS ice core box converted for use as an insulated generator box. Exhaust

vent is shown with metal duct tape to protect

box. Air intake vent is hidden behind strap."

- Solution to generator problems of 2006

- Surging and stalling of generator motor. Two new Honda 2 kW generators were purchased. These did not solve the problem alone and continued stalls meant the loss of 15 km of radar data along the traverse route and delays. Josh Swanson diagnosed the problem as icing in the carburetor, so an insulated box was made from a spare ICDS ice core box (Fig. 3). Small holes for exhaust and air intake allowed for ventilation and could be covered when not in use. The generator was stored in the heated Blue Room at night. This solution: keeping the generator warm when not in use and running in the insulated box, seemed to resolve the problem of stalling in temperatures below −30°C.

- The original request was for a diesel generator to reduce electrical noise that interferes with the radar signal reception. The hope was that the Honda generators with the RF “chip” would solve the problem. This year’s data proves that the RF chip does NOT reduce RF noise even to the level of the old Honda 1.8 kW alternator–type generator. While it’s possible that the newer inverter–type generator might work for relatively shallow surveys (<1,500 m ice thickness), they reduce the signal/noise too much for use in deeper ice surveys. Alternator–type gasoline generators or solar–powered systems should be used for deep surveys.

- Solar power for receiver computer was still inhibited by the lack of new reliable 100 amp–hr batteries (all were tasked to the power systems in the shelters). The solar panels and charge controller were used to assist in charging the smaller 35 amp–hr batteries for the transmitter. At least one of the new (“Vessel 2007”) 35 amp–hr batteries never held a charge. It might be necessary to look into solar charge controllers that are compatible with the new AGM batteries since they have a different voltage range than the older gel–cells.

- A suspension system for the radar shelter was requested last year in order to protect the radar equipment from the large sastrugi found on the plateau. A request for pneumatic air pillows (e.g. Firestone or Goodyear) was turned down based on concerns about temperature. Three ATV tires with inflated inner tubes were sent out to the winter–over site. These were sent back because there was no way to install them under the shelter in a manner that would distribute the weight properly. Josh Swanson (ASE–certified in suspension systems) believes that the pneumatic air suspensions should be just as reliable as tire inner tubes at cold temperatures. The addition of stabilizer bars would help keep the shelter in place.

Suggestions for US ITASE Platform as of 2007 season end:

As recommended by J. Swanson (mechanic) we suggest that the PB be returned to McMurdo for inspection and overhaul. The PB worked well for two seasons, but it is a fairly delicate vehicle and prone to fractures that are best inspected and repaired in a warm shop.Swanson also recommended a complete inspection and overhaul of the two Challenger 55s. To return these vehicles to McMurdo will require considerable effort since the 55 cabs must b e partially deconstructed. If these vehicles are to be used away from stations on future traverses they must be carefully inspected and given significant overhauls. This is well worth the time and cost since the vehicles served their purpose. Ideally mechanics should be deployed to South Pole to conduct inspection/overhaul there allowing these vehicles and their accompanying traverse sleds to remain as complete platforms. To reassemble these platforms requires considerable time, experience and care.

The traverse trains (Lehmans, Bercos with modules) should be left at South Pole intact. They are not the perfect traverse platform, but they are highly functional for certain activities.